LPG Solutions

Our checking equipment ensures precision and safety in LPG cylinder management. Our weight correction machines rectify inaccurate fills with on-the-spot correction through filling or evacuating LPG. Adaptable to various valves and sizes, they ensure accurate content and seamless installation.

Our check weighing systems offer rapid and accurate control over net content. These systems automatically identify under/overfilled cylinders, enhancing productivity with a capacity of up to 1,800 cylinders per hour.

Find the right solutions for your business here.

Checking equipment

Static check scale automatic in-line in chain conveyor

The electronically controlled static check scale is designed for in-line installation in a chain conveyor.

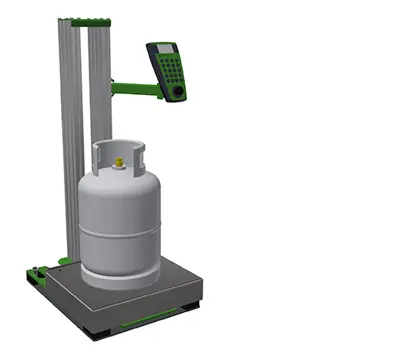

Static check scale manual stand-alone

The electronically controlled static check scale is designed for stand-alone installation.

Infrared leak test head CIR-II

The inherently and intrinsically safe infrared leak test head CIR-II is designed to be mounted on LPG leak detection units/machines that can fully automatically or manually test filled LPG cylinders for possible gas leaks.

Valve leak detector automatic in-line in chain conveyor

The electronically controlled valve leak detector is an independent unit designed for in-line installation in a chain conveyor.

Valve leak detector manual stand-alone

The manually operated valve leak detector is an independent unit designed for stand-alone installation.

Valve leak detector

The electronically controlled valve leak detector VLD is an independent unit designed for automatic in-line installation in a chain conveyor with valve opener/closer for screw valves.

Valve seal tester

The electronically controlled valve seal tester (for centre valves only) is an independent unit designed for automatic in-line installation in a chain conveyor.

Body leak detector

The electronically controlled body leak detector is designed with a rotating platform for stationary installation on the floor, with a connection to a chain conveyor system via automatic inlet and outlet units.

Weight correction machine

The electronically controlled weight correction machine is an independent unit designed for in-line installation in a roller conveyor or stand-alone installation.

Fully automatic tare reading

Discover how to speed up the tare encoding process, improve filling accuracy and avoid the hazards of over- and underfilled cylinders.

See more LPG Solutions

All of our LPG solutions are based on technology that delivers results. Find a complete overview of our systems and machines for LPG by clicking on the link below.

A unified product program for our LPG cylinder handling solutions is the logical next step in our quest to deliver the best to our customers. It means that we get the best of both worlds, with even more excellent products and customer support.

We still support Kosan Crisplant and Siraga products

Although we have combined their best qualities into a single MAKEEN Energy product line, we still support our customers who are using Kosan Crisplant or Siraga products in their filling operation. You can still receive spare parts or new machines from these brands, and our service offering for them remains unchanged.