Finishing equipment

Washing systems

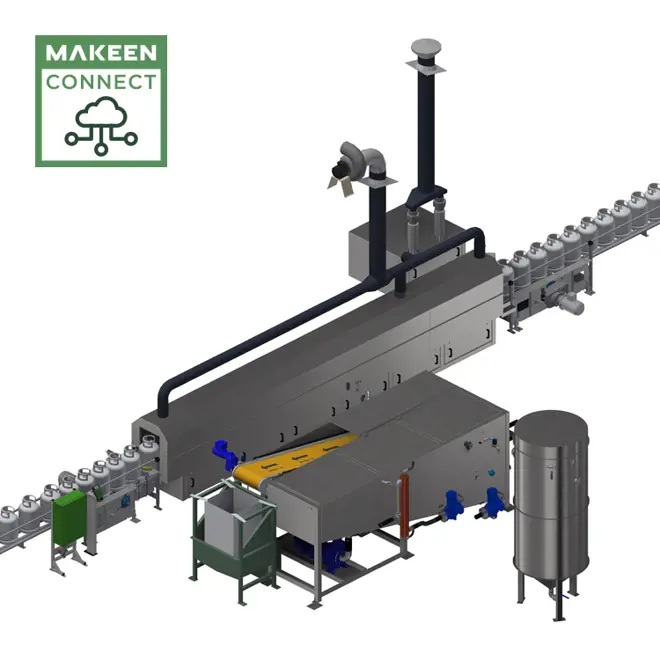

Compact tunnel with separate water tank and water treatment / Automatic in-line in chain conveyor

Finishing equipment

Compact tunnel with separate water tank and water treatment / Automatic in-line in chain conveyor

The automatic cylinder washing system WAS is an independent system designed for in-line installation in a chain conveyor. The WAS is designed as a compact tunnel that is insulated to minimize both heat loss and noise level from the washing and drying processes.

In the washing section of the tunnel, heated/pressurised soap water is sprayed onto the moving cylinders in all directions with arrays of nozzles.

The washed cylinders are blown dry with compressed air through a set of air blades in the drying section of the tunnel.

The water treatment/recirculation system ensures continuous operation with the lowest possible water consumption. A ventilation system minimises moisture release from the tunnel to the surrounding environment.

This system is compatible with MAKEEN Energy's Industry 4.0 Digital Solutions, which enables data capturing of the process for remote supervision, performance optimisation, and predictive/preventive maintenance alerts through e.g. a MAKEEN Energy cloud solution (optional).

Watch our video to see an example of a MAKEEN Energy LPG cylinder washing tunnel in operation.