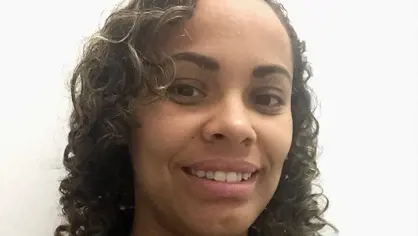

Meet a MAKEENer

Getting recognition for my work and not my title

How did your career start out?

Like most of the engineers from my school, I dreamed of working in the car industry. But that did not happen - instead, I accepted an invitation from one of my professors to work for his project engineering company. I worked on projects related to water distribution, heat transfer and air conditioning of shopping malls, restaurants, and hospitals.

When did you begin working with gas equipment?

After 1-1½ years in that company, I was ready to move on. At that time in Portugal, the natural gas business was really booming, and with that came a huge demand for engineers.

I had an interview at a company that was the reference on the Portuguese market for natural gas equipment - and for a whole year, nobody called me, so I thought I was forgotten. But then one day in 1999 they called me and said: "can you start next week? We are ready to move, and we would like to hire you."

I immediately said yes, because it would mean going around the country to do big things after over 2 years of only doing calculations and drawings at my desk. I travelled for training with manufacturers, often outside of Portugal. It was a great opportunity for a young person like me to progress and learn to work in a team.

So how did you end up in MGEPT?

Not long after I started, my company got an interest in LPG equipment. We had tried to compete with CPI (Consórcio Português Intercontinental), the leader in that market, but we found that it was difficult to take market share from them. It turned out, however, that CPI had a problem of succession. It was a family-owned company with aging managers and no-one from the family wanted to take over.

So, we thought: “if we can't beat them, why not buy them?". What I did not expect was when my boss told me "Tiago, we can buy this company, and I can make you the general manager." I thought he was joking - I was so young!

But he was not joking. In 2001, we took over CPI, and I became General Manager for CPI while also working for the company that bought it. But a few years after we acquired it, CPI was booming. It reached a point where I took the decision to dedicate myself 100% to CPI in 2004.

How did you approach your new leadership role?

I was the General Manager, but I was also packing and sending out goods, inspecting sites, etc. It was a small company at that time, only 2 people. In the beginning, it was a challenge, but I learned not to put too much in my job title: the main thing is just to make the company run, answer the phone, go to the customers, and things then happen naturally and positively. After a while, I became recognised as a good employee by the customers and the market. I enjoyed getting recognition for my work and not my title.

How did you become a part of MAKEEN Gas Equipment Portugal?

The same year we took over CPI, we became Kosan Crisplant's, now MAKEEN Gas Equipment, agent in Portugal. In 2005, they told us that they would like to extend their business to equipment and components. A Kosan Crisplant representative visited us for some weeks to see how we operate in CPI, what type of products we worked with and so on.

After some time, I think Kosan Crisplant realised that as a project-oriented company, they needed a separate, dedicated set of people working on equipment sales. In 2008, they offered to buy CPI. I was a minor shareholder in the company, and I said "why not? I'll sell it if there is a future for the company."

I think we were smart at the time because although we were doing well in Portugal, we also recognised the risks. We were selling 98% of our things in Portugal - what if the market went down? So, we sold the company to gain access to the network of Kosan Crisplant and the international markets. Today, there is no doubt in my mind that it was the right decision.

What does the future look like?

I think MAKEEN Gas Equipment has shown that it is possible to change the components distribution industry. We are changing it according to what we think is best for our customers. We are creating the trend of the industry, which is also recognised by some of the biggest LPG component producers - that is very motivating.

Sometimes it is all happening very fast: the speed at which we gain market is faster than the speed of growth in our organisation. Likewise, the acquisitions and integration of new companies within MAKEEN Gas Equipment demands a flexible and agile organisation. S24 bring us a set of tools (matrix organisation, digitalisation, One Global Team, etc.) making us more powerful and efficient to fulfil what is expected from us and providing the best of MAKEEN Gas Equipment into the market. It means we constantly must work on keeping the organisation side of our business up to par. It's exciting to see where it goes - we still have a lot of things ahead of us and the train keeps moving.