Reconditioning equipment

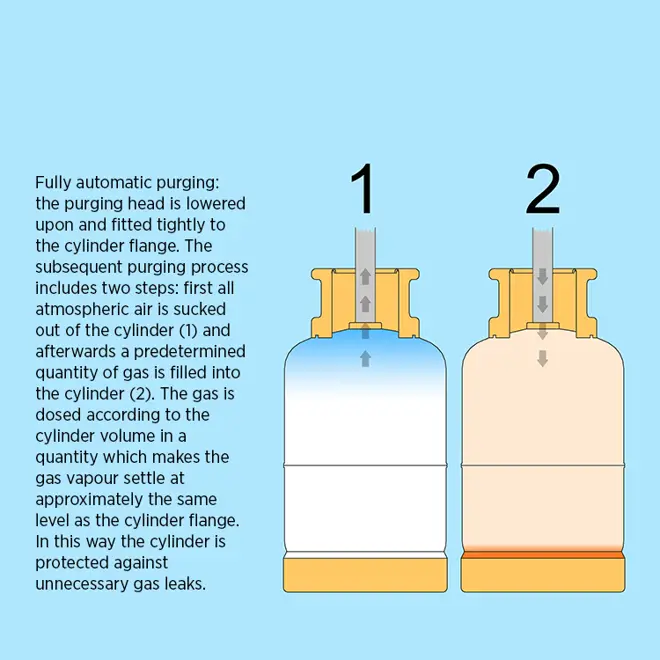

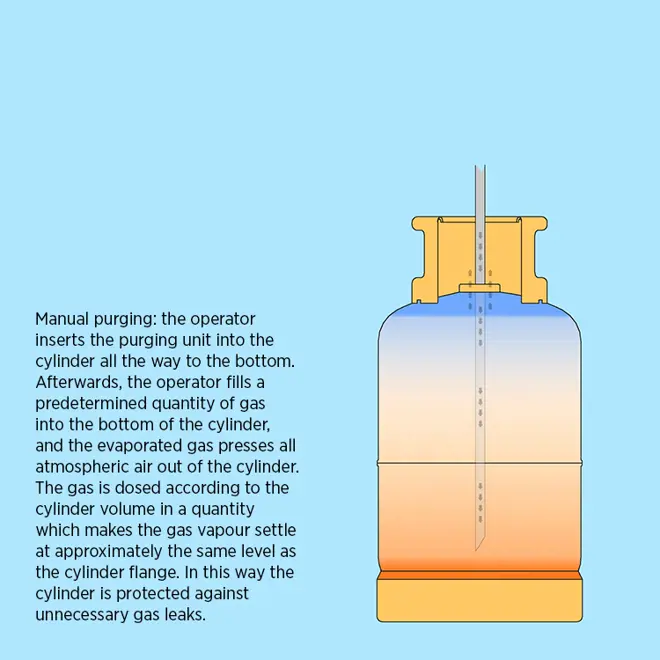

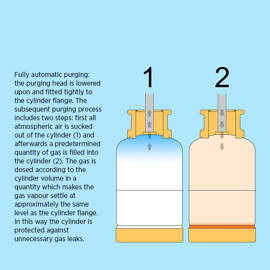

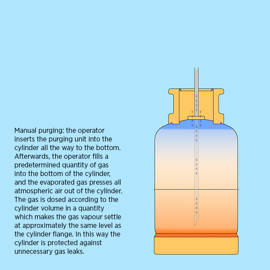

MAKEEN Energy's purging systems are designed for quick and safe replacement of atmospheric air in cylinders with LPG in vapour state. The process is applied on LPG cylinders without valves. Valves should be mounted right after the purging process.

- Avoid dangerous mix of LPG and atmospheric air in cylinders

- Filling speed at maximum level

- Avoid capacity reduction

- Controlled process: no dangerous aeration of cylinders after filling

- No aeration of cylinders when end-users start using them

Benefits

- High safety for end-users

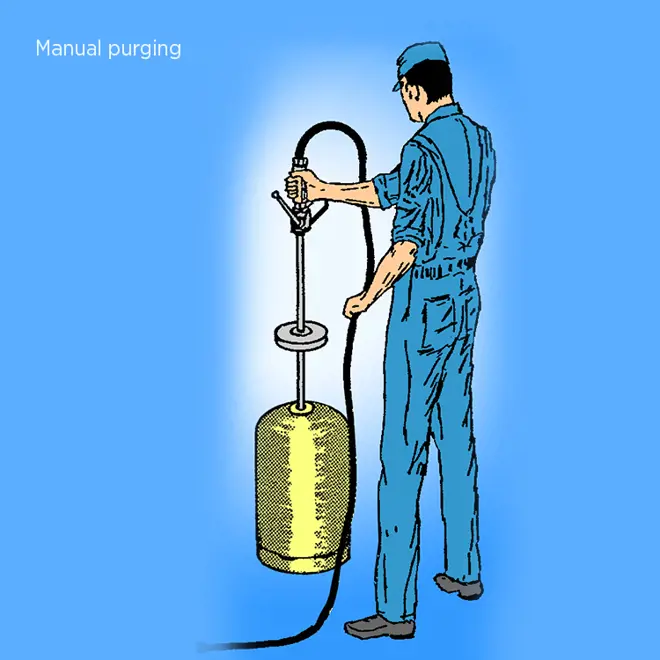

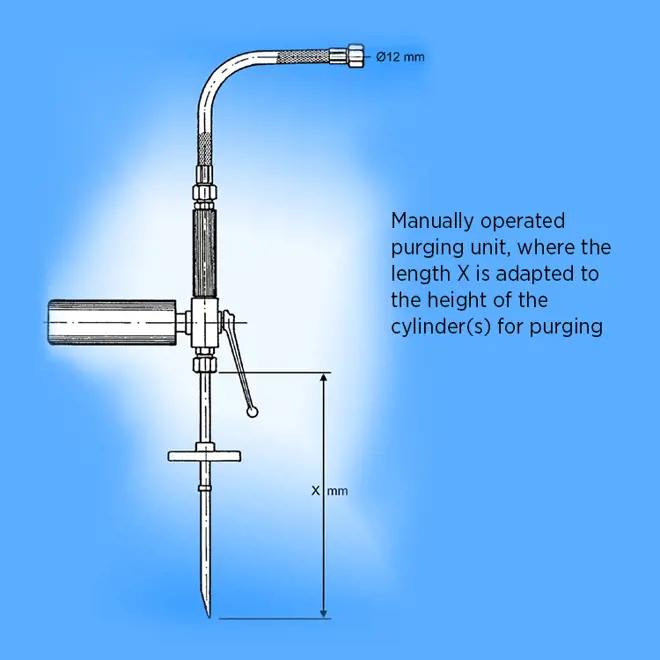

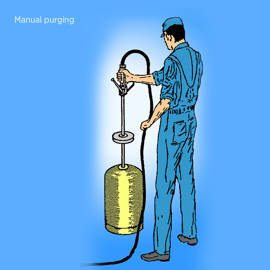

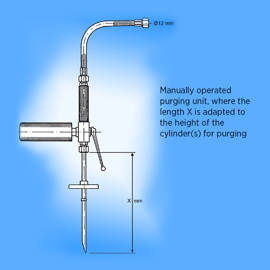

- Easy to use manual purging unit

- The manual purging unit requires minimum space

- Minimum maintenance

- Flexible to all cylinder diameters and heights

- Easy installation in existing plants

Possibilities

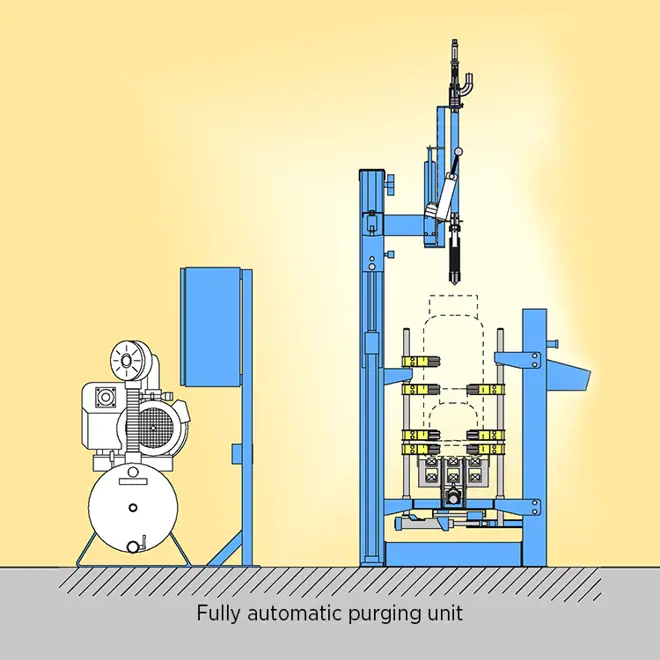

- Manuel, semiautomatic or automatic process

- Manual purging unit can be used as stand-alone unit or together with conveyor

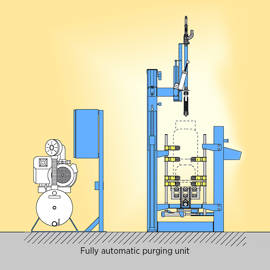

- Automatic purging is integrated in chain conveyor

- Dozing of variable quantity of LPG depending on cylinder size

- Vacuum suction and/or gas dosing

- Automatics for control of cylinder flow with manual purging unit in-line in chain conveyor

Safety

- Ex marking according to the ATEX Di-rective and applicable EN standards:

II 2G Ex h IIB T3 Gb

II 2G Ex h IIB T3 Gb - All purging systems are intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1

- All purging systems are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives