Handling and transport equipment

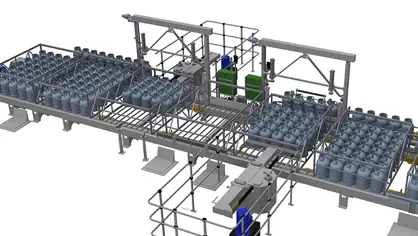

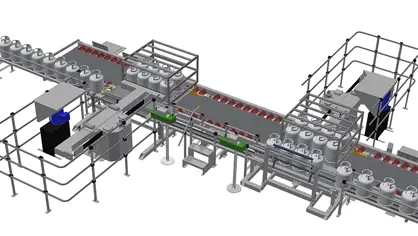

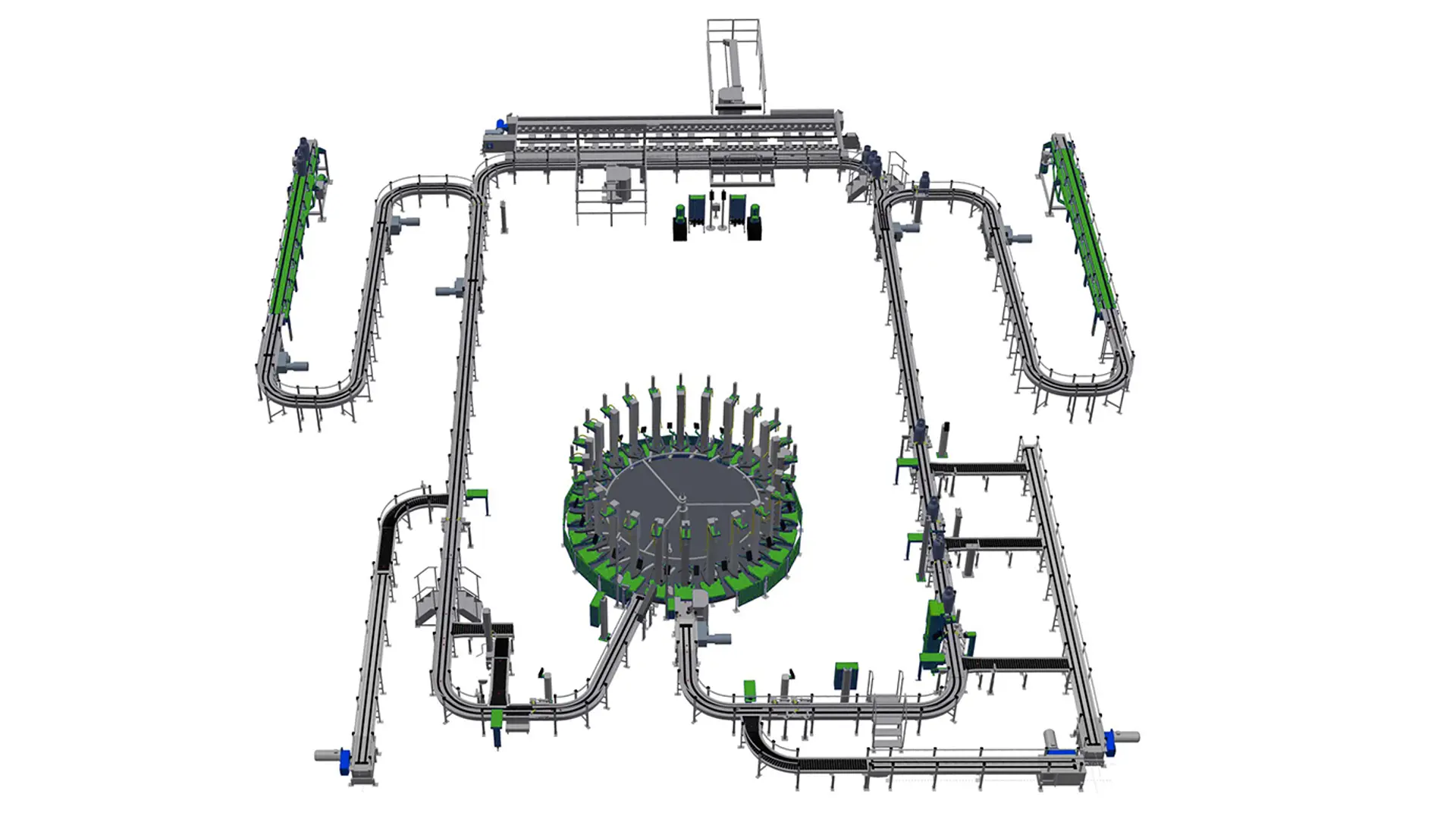

All chain conveyor systems are designed according to customer specifications (e.g. plant layout, cylinder types, etc.) for safe and efficient transport of LPG cylinders.

The cylinder transportation is fully automatic from the cylinder unloading point, passing various points of operation, to the cylinder loading point. Cylinders are transported on MAKEEN Energy’s conveyor chain MCC-30, uniquely designed to be compatible with the materials and dimensions of the conveyor tracks.

Benefits

Savings and safety

- Increased lifespan of the conveyor tracks due to optimised wear pattern of the MCC-30 chain

- Galvanised conveyor tracks and driving unit frames withstand corrosion in all weather conditions (long-lasting quality)

- Operator safety assurance with no manual cylinder handling (e.g. no injuries/strain)

- Increased cylinder life due to elimination of typical manual cylinder handling damages

Maximum production uptime

- Quick adjustable railings according to different cylinder diameters

- Quick replaceable wearing bar (fixed by few screws without need for fabrication)

Optimised production

- Fully automatic cylinder transport between the cylinder unloading and loading points (minimum manpower requirement)

- Adjustable chain conveyor speed according to operating conditions

- Highly efficient cylinder flow control with various automatic conveyor equipment (cylinder accumulation, stop, bypass, convergence, and divergence)

- Increased capacity due to optimisation of manual processes