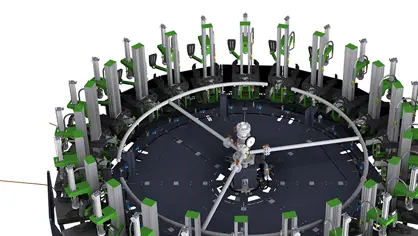

Filling equipment

MAKEEN Energy's mobile container filling plants are designed for safe and efficient filling, checking and maintenance of all kinds of LPG cylinders.

- Small flexible mobile and prefabricated plants – plug & play

- Ideal solution when entering and testing new markets

- Ideal filling solution when rebuilding/renovating existing plants

- Flexible solution and arrangement according to customer needs

- 20’ and 40’ containers, according to actual need for equipment

- Comprise Kosan Crisplant’s thoroughly tested standard filling equipment

- Filling capacity up to 400 cylinders per hour per container

- Complete filling plant (can also contain storage room, gatehouse and LPG tanks)

Benefits

- Easy installation on site

- Simple layout and maximum safety

- Minimum civil work and engineering

- The plant can be made independent of external power supply (e.g. in rural areas)

- Low power consumption

- Easy and safe to operate

- Ready for integration in filling system network

- Ready for communication with PC for data collection

- Comprise all necessary equipment for safe and reliable filling of gas cylinders

- Capacity increase is possible

Possibilities

- 1-8 filling machines

- Supply of standard filling plant equipment

- Supply of roller or chain conveyor

- Can be delivered as Turn Key projects including all equipment “within the fence”

Safety

- Ex marking according to the ATEX Di-rective and applicable EN standards:

II 2G Ex h IIB T3 Gb

II 2G Ex h IIB T3 Gb - All equipment and machines are intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1

- All equipment and machines are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives

- Filling machines and check scales have weighing Accuracy Classification C3 according to OIML R 76/EN45501