Knowledge Centre

Plastic has been a game-changer for a multitude of industries worldwide. Its durability, lightweight, and cost-effectiveness have made the material integral to modern life, found in everything from packaging and household items to medical devices and automotive parts.

Plastic is a versatile material made from polymers, which are long chains of molecules. These polymers are primarily derived from petroleum and natural gas. Plastics are composed mainly of carbon and hydrogen atoms, arranged in various configurations to create different types of plastic. Additives like colourants, stabilisers, and fillers are often included to enhance the plastic's properties, making it suitable for a wide range of applications.

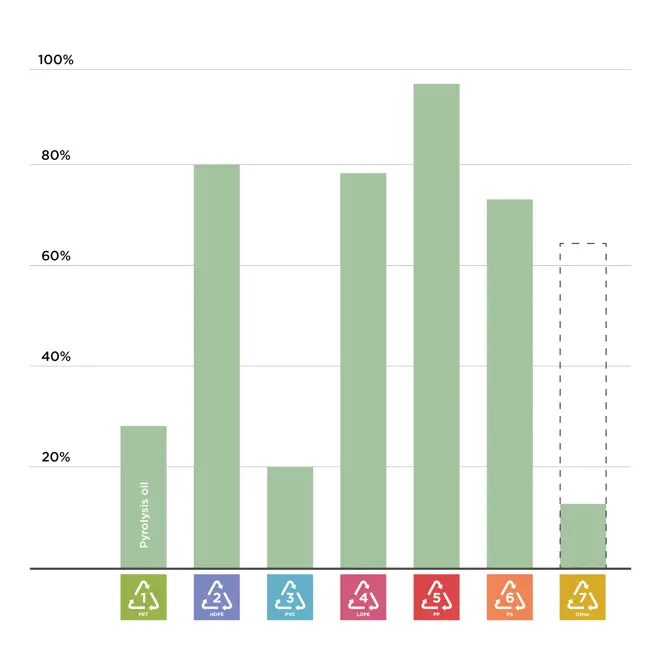

Plastics come in various types, each with distinct properties, applications, and compositions. These differences in composition control how much oil the material yields in a recycling process. Plastic types like polyethylene (PE) and polypropylene (PP), with higher hydrogen-to-carbon ratios, yield more oil. The structure of the plastic also matters; long, linear chains produce more oil than branched ones. Additives and fillers, used to enhance plastic properties, can reduce oil yield, and increase the gas and residue production. Higher-density plastics generally yield more oil, as they contain more hydrocarbons.

The seven types of plastic include:

- Polyethylene Terephthalate (PETE or PET)

- High-Density Polyethylene (HDPE)

- Polyvinyl Chloride (PVC)

- Low-Density Polyethylene (LDPE)

- Polypropylene (PP)

- Polystyrene or Styrofoam (PS)

- Miscellaneous plastics (includes polycarbonate, polylactide, acrylic, acrylonitrile butadiene, styrene, fiberglass, and nylon

Variations as the plastic consists of different types.

Polyethylene Terephthalate (PET)

PET is a strong, lightweight plastic commonly used in beverage bottles and food containers.

High-Density Polyethylene (HDPE)

HDPE is a durable plastic used in products like milk jugs, detergent bottles, and piping.

Polyvinyl Chloride (PVC)

PVC is a versatile plastic used in pipes, vinyl flooring, and medical equipment.

Low-Density Polyethylene (LDPE)

LDPE is used in plastic bags, six-pack rings, and various containers.

Polypropylene (PP)

PP is used in products like yogurt containers, bottle caps, and automotive parts.

Polystyrene (PS)

PS is used in disposable coffee cups, plastic food boxes, and packing foam.

Other Plastics (Resins, composites)

This category includes a variety of plastics such as polycarbonate, polylactide, acrylic, acrylonitrile butadiene, styrene, fibreglass, and nylon.

The future of plastic

The EU has introduced new waste management directives aimed at improving environmental sustainability and promoting a circular economy. Key regulations include stricter controls on waste exports, enhanced recycling targets, and the prohibition of plastic waste exports to non-OECD countries from November 2026.

The Waste Framework Directive is another cornerstone of EU waste management policy, setting ambitious recycling targets for municipal waste. By 2025, member states must achieve a minimum recycling rate of 55%, increasing to 60% by 2030 and 65% by 2035.

Additionally, the Packaging and Packaging Waste Directive aims to ensure that all packaging on the EU market is reusable or recyclable by 2030. It sets targets for reducing packaging waste, mandates the use of recycled content in plastic packaging.

However, the EU has yet to define or standardise the approach to chemical recycling. Despite being recognised by the European Union as a contributor to circular economy, there is still lacking regulatory framework for the process. As technology advances, a clearer path forward for chemical recycling must be defined to play a key role in recycling of plastic waste.

Other countries, such as the United States, Japan, Australia, South Korea, and Canada, have also implemented comprehensive waste management policies. These policies generally focus on reducing waste generation, enhancing recycling efforts, and ensuring proper disposal of hazardous materials. They promote the principles of reducing, reusing, and recycling waste, and often include extended producer responsibility schemes that hold manufacturers accountable for the entire lifecycle of their products.

Sources: New Regulation on waste shipments enters into force: New Regulation on waste shipments enters into force - European Commission (europa.eu) // Packaging waste - European Commission (europa.eu) // Packaging waste - European Commission (europa.eu) Waste Framework Directive: Waste Framework Directive - European Commission (europa.eu) Waste shipments: Waste shipments - European Commission (europa.eu) Environmental and economic assessment of plastic waste recycling: JRC Publications Repository - Environmental and economic assessment of plastic waste recycling (europa.eu)